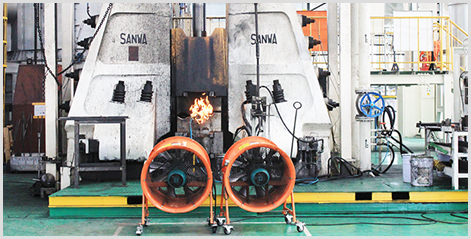

1. FORGING PROCESS

- 4T HAMMER ... 1 unit

4 Ton Hammer has the capacity of manufacturing forged parts up to 10 kg - 28 kg, Various size of knuckle, knuckle arm, tierod arm, and the pitman arm etc. - 1600 Ton Press ... 2 Unit

1600 ton press machine is able to manufacture Yoke parts for small size of propeller shafts, Gear used for small transmission, which are up to 1 kg - 3 kg for the each product.

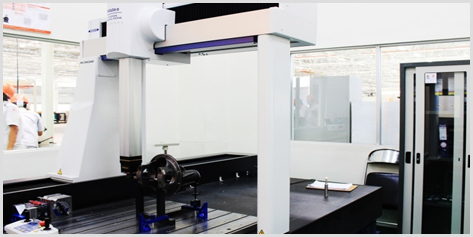

2. HEAT TREATMENT PROCESS

TJFI is capable of tempering and burning / refining forged parts and possesses to continuous heat treatment equipment.

「Main Specifications & its elements」- Product name :

Forged parts I-beam, knuckle, knuckle arm, etc. Maximum length: 2000 mm, width: 700

mm,

weight per unit: 105 kg to 1.6 kg - Material spec : Carbon steel (SC material), Alloy steel (chromium, molybdenum, etc.) ※ Any other refined steel is not included.

- Processing temperature : Quenching temperature: 850° C (Maximum: up to 900 ° C). Tempering temperature: 650 ° C (Maximum: up to 700 ° C).

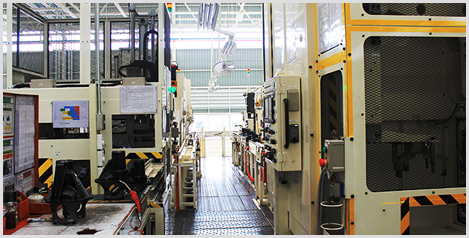

3. MACHINING PROCESS

- Various Axle Parts

Machining axle parts, such as I-beam, knuckle, knuckle arm, tie-rod arm, pitman arm, used for front axle assembly. - Small size of Front / Engine / Rear Axle casting

Parts

Machining of casted parts such as rotor, exhaust manifold, carrier & box, exported to Thailand. - Propeller shaft parts

Machining of forged parts processed by 1600T press machine.

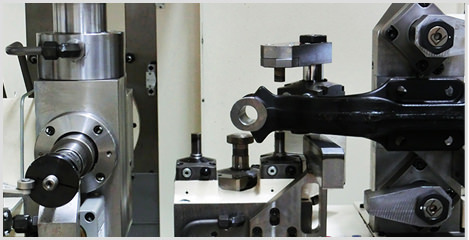

4. ASSEMBLY PROCESS

- Assembling the front axle

We assembly and provide various size of axle to Isuzu Astra Motor Indonesia, and also export the product to Thailand, Malaysia & Philippines. - Assembling the propeller shaft

We provide assembled small size of propeller shaft.

4 Ton Hammer

1600 Ton Press Machine

Machining Line

Axle Assembly Line

Propeler Assembly Line